Li-platform tsa granite air flotation ke tharollo e sebetsang bakeng sa lits'ebetso tsa indasteri le tsa khoebo. Ena ke theknoloji e tsoetseng pele e sebelisang moea o hatelletsoeng ho fanyeha lintho tse boima holim'a mosamo oa moea, e leng se etsang hore ho be bonolo ho tsamaisa lintho tse kholo le tse boima. Hangata e sebelisoa kahong, lipalangoangng le mafapheng ao ho 'ona mechini e meholo e hlokang ho tsamaisoa. Potso e atisang ho botsoa mabapi le li-platform tsa granite air flotation ke hore na li hloka tlhokomelo e sa khaotseng ho li boloka li sebetsa hantle. Sehloohong sena, re tla hlahloba sehlooho sena 'me re fane ka karabo ea potso ena.

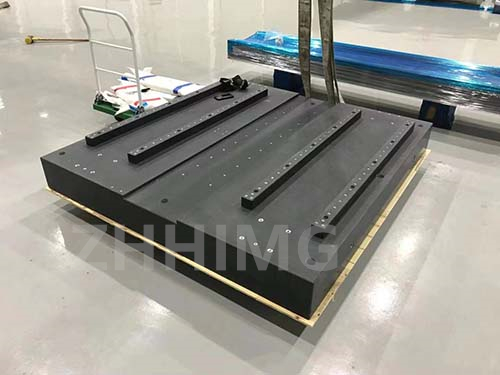

Li-platform tsa granite air flying ke theknoloji e sebetsang hantle le e tšepahalang e hlokang tlhokomelo e fokolang. E bonolo ka moralo 'me ha e hloke tsebo e ngata ea botekgeniki ho e sebelisa le ho e hlokomela. Sistimi ena e na le letoto la mekotla ea moea e pompeloang moeeng o hatelletsoeng, e leng se phahamisang mojaro holim'a mosamo oa moea. Sethala sa granite ka bosona se entsoe ka granite ea boleng bo holimo e hanelang ho tsofala le ho taboha 'me e etselitsoe ho tšoarella lilemo tse mashome ntle le tlhokomelo e kholo.

Leha ho le jwalo, jwalo ka mahlale ohle a sejwalejwale, di-platform tsa granite air flying platform di hloka boemo bo itseng ba tlhokomelo ho netefatsa hore di dula di sebetsa hantle ebile di sebetsa hantle. Ditlhoko tsa tlhokomelo di itshetlehile haholo-holo hodima kgafetsa ya tshebediso le mabaka a mang a tshebetso. Mohlala, haeba sethala se sebedisetswa ditshebediso tse boima, tse kang ho tsamaisa dijana tse kgolo, se ka hloka tlhokomelo e kgafetsa ho feta haeba se ne se sebedisetswa ditshebediso tse bobebe.

Mekhoa e tloaelehileng ea tlhokomelo bakeng sa liforomo tsa moea tse phaphametseng tsa granite e kenyelletsa ho hloekisa khafetsa, ho tlotsa likarolo tse tsamaeang, ho hlahloba mekotla ea moea, ho hlahloba li-compressor le litsamaiso tsa phepelo ea moea. Ts'ebetso ea ho hloekisa e kenyelletsa ho tlosa litšila, lerōle kapa lithōle tse ka 'nang tsa bokellana holim'a sethala. Sena se thusa ho thibela tšenyo ea mokotla oa moea le ho netefatsa hore sethala se lula se hloekile ebile se hloekile.

Mokhoa oa ho tlotsa o kenyelletsa ho sebelisa setlolo se loketseng likarolong tsohle tse tsamaeang ho fokotsa khohlano le ho tsofala. Sena se thusa ho atolosa bophelo ba tšebeletso ea sethala le ho se boloka se sebetsa hantle. Ho hlahloba mokotla oa moea le hona ho bohlokoa ho lemoha matšoao afe kapa afe a ho tsofala kapa tšenyo e ka 'nang ea hloka ho nkeloa sebaka.

Qetellong, ho hlahloba sistimi ea compressor le phepelo ea khase ho bohlokoa ho netefatsa phepelo e tsitsitseng ea moea o hatelletsoeng sethaleng. Mathata afe kapa afe ka sistimi ea phepelo ea khase a lokela ho rarolloa hang-hang ho thibela ho se sebetse kapa tšenyo sethaleng.

Ka bokhutšoanyane, liforomo tsa moea oa granite tse phaphametseng ke theknoloji e tšepahalang haholo le e sebetsang hantle e hlokang tlhokomelo e fokolang. Leha ho le joalo, ho hlokahala boemo bo itseng ba tlhokomelo ho boloka sethala se sebetsa hantle. Ho hloekisa khafetsa, ho tlotsa, ho hlahloba mekotla ea moea, ho hlahloba li-compressor le litsamaiso tsa phepelo ea khase ke tse ling tsa mekhoa ea mantlha ea tlhokomelo ea liforomo tsa moea oa granite tse phaphametseng. Ka ho latela mehato ena, sethala se ka sebelisoa ka mashome a lilemo ntle le litokiso tse kholo kapa ho nkeloa sebaka, ho fana ka tharollo e theko e tlaase bakeng sa lits'ebetso tse ngata tsa indasteri le tsa khoebo.

Nako ea poso: Mots'eanong-06-2024