Li-spindle tsa granite le litafole tsa mosebetsi ke likarolo tsa bohlokoa tlhahisong ea lisebelisoa tsa mochini tse nepahetseng haholo, lisebelisoa tsa ho lekanya, le lisebelisoa tse ling tsa indasteri. Li bapala karolo ea bohlokoa ho netefatseng ho nepahala le botsitso ba mechini ena, e leng habohlokoa bakeng sa ho fihlela litlhoko tse tobileng tsa liindasteri tsa sejoale-joale. Leha ho le joalo, ho nepahala le botsitso ba li-spindle tsa granite le litafole tsa mosebetsi li ka angoa ke mabaka a fapaneng, ho kenyeletsoa le liphoso tsa tlhahiso, thepa ea thepa le maemo a tikoloho. Ka hona, ho bohlokoa ho nka mehato e nepahetseng ho netefatsa boleng le ts'epo ea tsona.

Tsela e 'ngoe e sebetsang ea ho netefatsa ho nepahala le botsitso ba li-spindle tsa granite le litafole tsa mosebetsi ke ho sebelisa mochini o lekanyang oa coordinate (CMM) bakeng sa tlhahlobo le netefatso. CMM ke sesebelisoa sa ho lekanya se nepahetseng haholo se ka fanang ka litekanyo tse nepahetseng le tse tšepahalang tsa lintho tse rarahaneng tsa mahlakore a mararo tse nang le ho nepahala ha maemo a tlase a micron. Ka ho sebelisa CMM ho lekanya le ho netefatsa litekanyo, mamello le litšobotsi tsa jeometri tsa li-spindle tsa granite le litafole tsa mosebetsi, bahlahisi ba ka lemoha ho kheloha kapa liphoso leha e le life 'me ba nka mehato ea ho lokisa.

Ha o sebedisa CMM ho lekanya dikarolo tsa granite, ho bohlokwa ho ela hloko dintlha tse mmalwa ho netefatsa diphetho tse nepahetseng le tse tshepahalang. Sa pele, CMM e lokela ho lekanngwa le ho netefatswa kgafetsa ho netefatsa ho nepahala le botsitso ba yona. Sena se ka fihlellwa ka ho etsa tlhahlobo e ka latelwang ya CMM ho ya ka maemo a matjhaba, jwalo ka ISO 10360. Sa bobedi, tshebetso ya tekanyo e lokela ho reriwa le ho etswa ka hloko ho qoba diphoso tsa tekanyo le ho netefatsa hore e ka phetwa hape. Sena se kenyeletsa ho kgetha mawa a nepahetseng a tekanyo, ho beha di-probe tse loketseng tsa tekanyo, le ho kgetha diforeimi tse nepahetseng tsa referense le ditsamaiso tsa ho hokahanya.

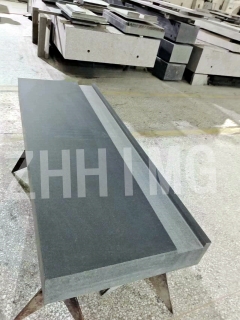

Karolo e 'ngoe ea bohlokoa ea ho netefatsa boleng ba li-spindle tsa granite le litafole tsa mosebetsi ke ho laola ts'ebetso ea tlhahiso ka hloko. Sena se kenyelletsa ho sebelisa thepa e tala ea boleng bo holimo, joalo ka li-granite tse hloekileng haholo tse nang le li-coefficient tse tlase tsa katoloso ea mocheso le botsitso bo botle ba mechini, le ho sebelisa mekhoa e tsoetseng pele ea tlhahiso, joalo ka ho sila ka nepo, ho lahlela le ho polishing. Bahlahisi ba lokela ho nka mehato ea ho qoba liphoso tsa sebopeho, joalo ka mapetso, likheo le lintho tse kenyellelitsoeng, tse ka amang botsitso le thepa ea mechini ea likarolo tsa granite.

Maemo a tikoloho a ka boela a ama ho nepahala le botsitso ba dikarolo tsa granite. Mohlala, ho feto-fetoha ha mocheso ho ka baka katoloso kapa ho honyela ha granite mochesong, e leng se lebisang diphetohong tsa boholo le ho feto-fetoha ha tsona. Ho fokotsa ditlamorao tsa ho se tsitse ha mocheso, bahlahisi ba ka nka mehato e fapaneng, jwalo ka ho kenya dikobo tse tsitsitseng mochesong, ho sebedisa mekgwa ya puseletso ya mochesong, le ho fokotsa mehlodi ya mocheso haufi le dikarolo tsa mochini wa granite. Ka ho tshwanang, diphetoho tsa mongobo di ka baka diphetoho tsa boholo ka lebaka la ho monya mongobo kapa ho ntsha metsi. Ho qoba sena, bahlahisi ba ka boloka le ho sebedisa dikarolo tsa granite tikolohong e laolwang ya mongobo.

Qetellong, ho netefatsa ho nepahala le botsitso ba li-spindle tsa granite le litafole tsa mosebetsi ke habohlokoa bakeng sa ho fihlela ho nepahala le ho tšepahala ho hoholo lits'ebetsong tsa tlhahiso ea sejoale-joale. Ka ho sebelisa mekhoa e tsoetseng pele ea ho lekanya le ho hlahloba, ho laola ts'ebetso ea tlhahiso, le ho fokotsa litlamorao tsa maemo a tikoloho, bahlahisi ba ka hlahisa likarolo tsa granite tsa boleng bo holimo tse fihlelang litlhoko tse thata ka ho fetisisa tsa indasteri.

Nako ea poso: Mmesa-09-2024