Lisebelisoa tsa ho lekanya ka mokhoa o nepahetseng oa granite (babusi ba lisekoere, li-straightedges, babusi ba Angle, joalo-joalo) ba phetha karolo ea bohlokoa masimong a mangata a phahameng ka lebaka la ho nepahala ha bona, botsitso bo phahameng le ho hanyetsa ho matla ha kutu.

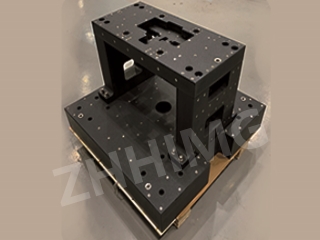

Ts'ebetsong e nepahetseng ea mochini, e sebelisetsoa ho lekanya ho otloloha ha liporo tsa tataiso le ho bata ha lithaelese tsa lisebelisoa tsa mochini oa CNC, litsi tsa machining le lisebelisoa tse ling. Ka coefficient ea ho atolosa mocheso e tlase (4-8) × 10⁻⁶/℃, e ka hanyetsa tšusumetso ea ho phahama ha mocheso nakong ea ts'ebetso ea lisebelisoa tsa mochine. Ha u lekola likarolo tse nepahetseng, bokaholimo ba eona bo tlase bo ke ke ba ngopa sesebediswa mme bo hanana le ho bola ha oli.

Liindasteri tsa lifofane le tsa ts'ireletso li na le litlhoko tse tiileng tsa ho nepahala. Lisebelisoa tsa ho lekanya tsa granite li sebelisetsoa ho lekanya lisebelisoa tsa tenon tsa mahare a enjene ea lifofane le ho hlahloba libaka tse mating tsa li-missile cabins, joalo-joalo. Tšobotsi ea eona e phahameng ea mongobo e ka monya ho thothomela ha workshop. E na le botsitso bo matla ba lik'hemik'hale 'me e ka ikamahanya le tikoloho e khethehileng ea ts'ebetso ea workshop ea aerospace, ho netefatsa ho nepahala ha tlhahiso ea likarolo tsa bohlokoa.

Lefapheng la tlhahiso ea lisebelisoa tsa elektroniki le tsa semiconductor, lisebelisoa tsa ho lekanya tsa granite li sebelisoa bakeng sa ho lekanya liporo tsa tataiso ka har'a lisebelisoa tse joalo ka mechini ea photolithography le mechini ea ho qoelisa ka liphaephe, hammoho le tlhahlobo ea lisebelisoa tsa ho paka li-chip. Tšobotsi ea eona ea ho se be le pula ea ion ea tšepe e qoba ho silafatsa workshop e hloekileng ea semiconductor, ho netefatsa ho nepahala ha nano-scale lithography le boleng ba SMT patch soldering.

Liteko tsa Metrology le litsi tsa lipatlisiso li sebelisa lisebelisoa tsa ho lekanya tsa granite e le litekanyetso ho lekanya lisebelisoa tse ling tsa ho lekanya tšepe. Li na le ts'ebetso e ntle ea nako e telele ea ho nepahala, 'me phetoho ea ho bata ka mor'a lilemo tse 10 tsa tšebeliso ke ≤± 0.5μm/m. E boetse e sebelisoa hangata joalo ka litšupiso tsa tekanyo e nepahetseng haholo ho mahlale a thepa le litekong tsa boenjiniere ba optical.

Ho feta moo, lisebelisoa tsa ho lekanya granite li boetse li sebelisoa ha ho etsoa lisebelisoa tsa bongaka le lisebelisoa tsa optical, joalo ka ho lekanya manonyeletso a liroboto tsa ho buoa le metheo ea li-brackets tsa bolepi ba linaleli, ho etsa bonnete ba hore sesebelisoa se fihlela boemo bo nepahetseng ba limilimithara tse tlase le litlamorao tsa ho shebella ntle le ho kheloha. Ka ts'ebetso e ikhethang, lisebelisoa tsa ho lekanya ho nepahala ha granite li fetohile "lejoe la sekhutlo le nepahetseng" la tlhahiso ea maemo a holimo.

Nako ea poso: May-22-2025