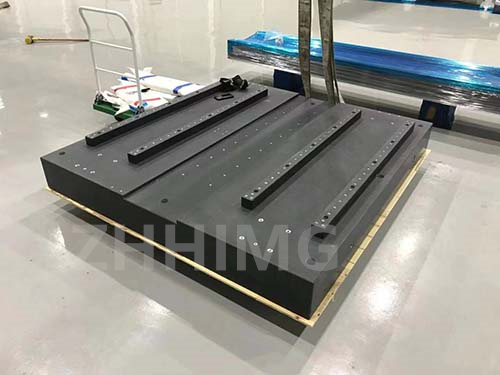

Li-bearing tsa khase tsa granite ke e 'ngoe ea mahlale a tsoetseng pele ka ho fetisisa a sebelisitsoeng lisebelisoa tsa CNC. Li fana ka melemo e mengata mochining 'me li na le mefuta e mengata ea lits'ebetso. Mona ke tse ling tsa lits'ebetso tsa li-bearing tsa khase tsa granite lisebelisoa tsa CNC:

1. Mechini e Potlakileng: E 'ngoe ea melemo ea bohlokoa ka ho fetisisa ea li-bearing tsa khase tsa granite ke bokhoni ba tsona ba ho etsa mechini e potlakileng. Sena se bakoa ke ho nepahala ha tsona ho phahameng le bokaholimo bo tlase ba khohlano bo etsang hore li be ntle bakeng sa tšebeliso ea lisebelisoa tsa CNC, e leng se hlokang mechini e potlakileng bakeng sa ho nepahala le katleho.

2. Botsitso le ho Tšoarella: Botsitso le ho tšoarella ha li-bearings tsa khase tsa granite lisebelisoa tsa CNC ha li bapisoe. Li fana ka motheo o tsitsitseng le o tiileng bakeng sa mochini, li netefatsa hore o ka mamella lihora tse telele tsa ts'ebetso ntle le ho senyeha kapa ho se sebetse hantle.

3. Ho Fokotsa ho Tsitsinyeha le Lerata: Li-bearing tsa khase tsa granite li tsebahala ka bokhoni ba tsona ba ho fokotsa ho thothomela le lerata mechineng. Lebaka ke hobane ha li na kamano ea tšepe, e leng se felisang monyetla oa khohlano, 'me ka hona, ha ho lerata le hlahisoang nakong ea ts'ebetso.

4. Tlhokomelo e Tlase: Mechini ea CNC e sebelisang li-bearing tsa khase ea granite e na le litlhoko tse tlase tsa tlhokomelo. Ho fapana le li-bearing tsa bolo tsa setso, li-bearing tsa khase ea granite ha li hloke tlhokomelo, e leng se etsang hore li be bonolo ebile li boloke nako.

5. Ho Nepahala ho Eketsehileng: Tšebeliso ea li-bearing tsa khase tsa granite lisebelisoa tsa CNC e tiisa ho nepahala le ho nepahala ho eketsehileng. Ka bokaholimo ba tsona bo tlase ba khohlano, li ka boloka mamello e tiileng nakong ea ts'ebetso ea ho sebetsa ka lebelo le phahameng, e leng se fellang ka likarolo tsa boleng bo holimo.

6. Bokgoni ba Matla: Di-bearing tsa khase tsa granite di fana ka bokgoni bo eketsehileng ba matla. Lebaka ke hobane di hloka matla a fokolang ho sebetsa, mme ka lehlakoreng le leng, di hlahisa mocheso o fokolang. Sena se fokotsa tlhoko ya ditsamaiso tsa ho phodisa, e leng se fetolelang ho fokotsa dibili tsa matla le ho fokotsa kganya ya khabone.

7. E Sireletsa Tikoloho: Li-bearing tsa khase tsa granite li sireletsa tikoloho. Ha li hloke setlolo, e leng se felisang tlhoko ea oli le lik'hemik'hale tse ling tse sebelisoang li-bearing tsa setso. Sena, le sona, se fokotsa litšila le ho fokotsa tšusumetso ea mochini tikolohong.

Qetellong, lits'ebetso tsa li-bearing tsa khase ea granite lisebelisoa tsa CNC li ngata ebile li bohlokoa. Li fana ka melemo e mengata, ho kenyeletsoa le ho sebetsa ka lebelo le phahameng, botsitso le ho tšoarella, ho thothomela le lerata le fokotsehileng, tlhokomelo e tlase, ho nepahala ho eketsehileng, ts'ebeliso e ntle ea matla le botsoalle ba tikoloho. Ka hona, ke letsete le molemo bakeng sa mong'a mochini ofe kapa ofe oa CNC ea batlang ho ntlafatsa ts'ebetso ea lisebelisoa tsa hae.

Nako ea poso: Hlakubele-28-2024