Tataiso ea ho Sebetsa le ho Hlokomela Poleiti ea Granite: Poleiti ea granite e nepahetseng e hloka ho sebetsa le ho hlokomela ka mokhoa o khethehileng ho netefatsa ho nepahala ha eona le ho phela nako e telele. Pele e polishwa, karolo ea granite e tlameha ho etsoa ts'ebetso ea pele ea mochini le ho fetoloa ka mokhoa o otlolohileng ho latela melao-motheo ea ho beha likhutlo li tharo. Kamora ho sila ka mokhoa o otlolohileng, haeba ho sebetsa ka mokhoa o otlolohileng oa CNC ho sa khone ho fihlela ho nepahala ho hlokahalang—hangata ho fihlela ho nepahala ha Kereiti ea 0 (mamello ea 0.01mm/m joalo ka ha ho boletsoe ho DIN 876)—ho qeta ka letsoho hoa hlokahala bakeng sa ho fihlela limaraka tse phahameng tsa ho nepahala joalo ka Kereiti ea 00 (mamello ea 0.005mm/m ho latela maemo a ASTM B89.3.7).

Ts'ebetso ea ho sebetsa ka thata e kenyelletsa mehato e 'maloa ea bohlokoa. Ea pele, ho sila ka thata ho theha ho ba bataletseng ha motheo, ho lateloa ke ho qeta habeli ho tlosa matšoao a ho sebetsa ka thata. Ho sila ka nepo, hangata ho etsoang ka letsoho, ho ntlafatsa bokaholimo ho fihlela mamello e lakatsehang ea ho ba bataletseng le ho ba bataletseng ha bokaholimo (Boleng ba Ra ba 0.32-0.63μm, moo Ra e emelang ho kheloha ho tloaelehileng ha boemo ba bokaholimo). Qetellong, tlhahlobo e hlokolosi e netefatsa ho latela maemo a tekheniki, ka lintlha tsa tekanyo tse behiloeng ka mokhoa o bohlale ho pholletsa le diagonal, mathōko le midlines - hangata lintlha tse 10-50 ho latela boholo ba poleiti - ho netefatsa tlhahlobo e ts'oanang ea ho nepahala.

Ho sebetsana le ho kenya ho ama ho nepahala haholo. Ka lebaka la ho tiea ha granite ka tlhaho (bothata ba Mohs 6-7), ho phahamisa ho sa lokelang ho ka baka phetoho e sa feleng. Bakeng sa lits'ebetso tsa bohlokoa tse hlokang ho nepahala ha Grade 00, ho lahlela ka letsoho kamora ho kenya ho bohlokoa ho khutlisetsa ho nepahala ho senyehileng nakong ea lipalangoang. Tlhokomelo ena ho lintlha e khetholla lipoleiti tsa bokaholimo ba granite tse nepahetseng tsa premium ho tsoa ho mefuta e tloaelehileng e entsoeng ka mechini.

Mekhoa ea tlhokomelo e ama ka ho toba ts'ebetso le bophelo ba eona. Qala ka ho hloekisa ka botlalo u sebelisa li-cleaner tsa pH tse sa nke lehlakore—qoba lintho tse nang le asiti tse ka hlabang bokaholimo. Tekanyo ea selemo le selemo ka li-interferometer tsa laser, tse ka lateloang ho latela maemo a NIST, e netefatsa ho nepahala ho tsoelang pele. Ha u beha likarolo tsa mosebetsi, lumella ho leka-lekana ha mocheso (hangata metsotso e 15-30) ho thibela liphoso tsa tekanyo ho tsoa liphapang tsa mocheso. Le ka mohla u se ke ua thellela lintho tse khorofo holim'a bokaholimo, kaha sena se ka baka mengoapo e menyenyane e amang ho batalla.

Tataiso e nepahetseng ea tšebeliso e kenyelletsa ho hlompha meeli ea mojaro ho thibela ho fetoha ha sebopeho, ho boloka maemo a tikoloho a tsitsitseng (mocheso oa 20±2°C, mongobo oa 50±5%), le ho sebelisa lisebelisoa tse khethehileng tsa ho phahamisa ho qoba tšenyo ea sefofane se petsohileng. Ho fapana le lintho tse tšoanang le tsa tšepe, botsitso ba mocheso oa granite (0.01ppm/°C) bo fokotsa litšusumetso tsa tikoloho, empa liphetoho tsa mocheso tse potlakileng li ntse li lokela ho qojoa.

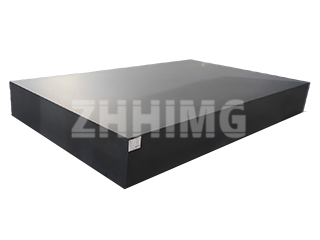

Jwalo ka sesebediswa sa motheo ho metrology e nepahetseng, dipoleiti tsa bokahodimo tsa granite tse netefaditsweng (tse netefaditsweng ke ISO 17025) di sebetsa e le tekanyetso ya tshupiso bakeng sa ditekanyo tsa boholo. Tlhokomelo ya tsona e hloka boiteko bo fokolang—hlakola feela ka lesela le se nang lesela kamora ho di sebedisa—ha ho hlokahale dikobo tse ikgethang kapa ditlolo. Ka ho latela diprothokholo tsena tsa ho sebetsa le tlhokomelo, dipoleiti tsa bokahodimo tsa granite tse nepahetseng di fana ka tshebetso e tshepahalang ka mashome a dilemo, e leng se etsang hore e be tsa bohlokwa haholo dilaboratoring tsa ho lekanya, tlhahisong ya difofane, le ditshebedisong tsa boenjiniere bo nepahetseng haholo.

Nako ea poso: Pulungoana-19-2025