Liholong tse khutsitseng tsa lilaboratori tsa ho lekanya, likamore tsa ho hlwekisa tsa semiconductor, le lisuite tsa metrology tsa lifofane, phetoho e khutsitseng e ntse e tsoela pele. Ha e khannoe ke software kapa li-sensor feela—empa ke thepa e etsang motheo oa tekanyo ka boeona. Ka pele ho phetoho ena ho na le lisebelisoa tse tsoetseng pele tsa ho lekanya tsa ceramic, ho kenyeletsoa le 'musi oa ceramic air straight ruler o tsitsitseng haholo le silicon-carbide e tiileng haholo e nang le sekoere (Si-SiC). Tsena ha se lisebelisoa feela; ke lintho tse thusang mehla e mecha moo botsitso, ho pheta-pheta, le ho se nke lehlakore ha mocheso ho ke keng ha buisanoa.

Ka nako e fetang mashome a mahlano a lilemo, granite e ntšo e ne e laola metrology e nepahetseng. Ho fifala ha eona ka tlhaho, katoloso e tlase ea mocheso, le ho batalatsa ho babatsehang ho entse hore e be thepa e ratoang bakeng sa lipoleiti tsa bokaholimo, lisekoere le mathoko a otlolohileng. Leha ho le joalo, ha liindasteri li ntse li kenella ho mamello ea sub-micron esita le nanometer-haholo-holo ho semiconductor lithography, space optics, le quantum computing-mefokolo ea granite e se e ntse e totobala haholo. E boima, e kotsing ea ho qhekelloa ha micro-chipping tlas'a ho kopana khafetsa, 'me, ho sa tsotellehe botumo ba eona, e ntse e bontša ho thekesela ho honyenyane ha nako e telele tlas'a mojaro kapa phetoho ea tikoloho.

Kena ka hara di-ceramic tse entsweng ka boqapi: ha se dipitsa tse pshatlehang habonolo tsa monahano wa letsatsi le letsatsi, empa ke thepa e teteaneng, e tshwanang, e sebetsang hantle e entsweng tlasa mocheso o feteletseng le kgatello. Har'a tsena, dihlopha tse pedi di hlahella bakeng sa ditshebediso tsa metrology: alumina e hlwekileng haholo (Al₂O₃) le carbide ya silicon e tlamilweng ka karabelo (Si-SiC). Le hoja ka bobedi di fana ka dintlafatso tse kgolo hodima thepa ya setso, di sebeletsa mesebetsi e fapaneng—mme mmoho, di emela moedi wa se ka kgonehang metrologyng ya dimensional.

Nka mohlala, rulara e otlolohileng ea moea ea ceramic. E etselitsoe ho sebelisoa le mekhahlelo e jereng moea kapa li-interferometer tsa optical, sesebelisoa sena se hloka ho otloloha ho batlang ho phethahetse, boima bo fokolang, le ho se khelohe ha mocheso.babusi ba letsopa—e entsoe ho fihlela e bataletse ebile e otlolohile ka hare ho ±0.5 µm ho feta 500 mm mme e bentšitsoe ho fihlela e le ho hlaka ka tlase ho Ra 0.02 µm—e fana ka seo hantle. Boima ba tsona bo tlase (~3.6 g/cm³) bo fokotsa ho se sebetse hantle litsamaisong tsa tekanyo e matla, ha tlhaho ea tsona e seng ea makenete, e sa tsamaiseng motlakase e felisa tšitiso libakeng tse bonolo tsa elektroniki kapa tsa makenete. Lisebelisoang tsa tlhahlobo ea wafer kapa li-setting tsa ho lekanya tsa laser tracker, moo esita le micron ea seqha e ka sothang liphetho, rulara ea moea o otlolohileng oa ceramic e fana ka referense e tsitsitseng, e sa sebetseng hantle e lulang e le 'nete ho pholletsa le liphetoho tsa mocheso le lipotoloho tsa ts'ebetso.

Empa ha ho hlokahala ho tiea ho hoholo le ho tsamaisa mocheso—joalo ka ho hokahanya seipone sa sebonela-hōle kapa ho lekanya ha laser cavity ka matla a phahameng—baenjiniere ba retelehela ho likarolo tse nang le silicon-carbide (Si-SiC) tse nang le lipeipi tse nang le boleng bo holimo le tse sekoere. Si-SiC ke e 'ngoe ea thepa e thata ka ho fetisisa e tsejoang, ka modulus ea Young e fetang 400 GPa—e fetang makhetlo a mararo ho feta ea tšepe—'me ho tsamaisa mocheso ho tšoana le aluminium. Ha e le hantle, coefficient ea eona ea katoloso ea mocheso (CTE) e ka etsoa hore e tšoane le ea likhalase tsa optical kapa li-wafer tsa silicon, e leng se nolofalletsang katoloso e fapaneng ea hoo e ka bang zero likopanong tse kopantsoeng. Sekwere sa Si-SiC se sebelisoang e le referense e kholo sesebelisoa sa lithography sa EUV se ke ke sa tšoara sebopeho sa sona feela—se tla hanela ho sotheha ho bakoang ke ho futhumala kapa ho thothomela ha sebaka.

Se etsang hore litlhōlo tsena li khonehe ha se thepa feela, empa ke tsebo ea ho etsa lisebelisoa tsa ho lekanya tsa letsopa. Ho sebetsa ka nepo ha Si-SiC, mohlala, ho hloka mabili a silang a taemane, liforomo tsa CNC tse ka tlase ho micron, le lits'ebetso tsa ho lata mekhahlelo e mengata tse etsoang libakeng tse laoloang ke mocheso. Esita le khatello e nyane e setseng e bakoang ke ho sintering ho sa lokelang e ka lebisa ho warpage ea kamora mochini. Ke ka lebaka leo bahlahisi ba 'maloa feela ba lefats'e ba khethiloeng ba kopanyang tlhahiso ea thepa, ho theha ka nepo, le metrology ea ho qetela tlas'a marulelo a le mong - bokhoni bo arolang bahlahisi ba 'nete ba sehlopha sa metrology ho bafani ba kakaretso ba letsopa.

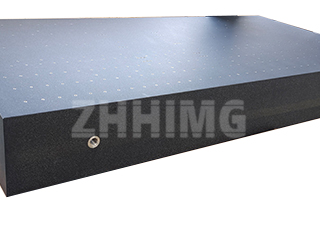

Ho ZHONGHUI INTELLIGENT MANUFACTURING (JINAN) GROUP CO., LTD (ZHHIMG), kopanyo ena e otlolohileng ke ea bohlokoa thomong ea rona. Lisebelisoa tsa rona tsa ho lekanya tsa letsopa—ho kenyeletsoa le mehlala ea ceramic air straight ruler e netefalitsoeng ho DIN 874 Kereiti ea AA le lintho tsa khale tse nang le silicon-carbide (Si-Si-C) tse nang le li-parallelepipe le tse sekwere tse ka lateloang ho latela maemo a PTB le NIST—li hlahisoa ka likamoreng tsa ho hloekisa tsa ISO Class 7 ho sebelisoa li-protocol tsa sintering le tsa ho qeta tse ikhethileng. Karolo e 'ngoe le e 'ngoe e feta netefatsong e felletseng ea interferometric, netefatso ea CMM ea mamello ea geometri (ho batalla, ho tšoana, ho ema hantle), le tlhahlobo ea botšepehi ba bokaholimo pele ho romelloa. Sephetho ke ntho ea khale ea referense e sa fihlelleng litlhaloso feela—e li feta ka mokhoa o tsitsitseng ho pholletsa le lihlopha.

Tlhoko ea ts'ebetso e joalo e ntse e eketseha. Tlhahisong ea li-semiconductor, litsamaiso tsa lithography tsa EUV le tsa NA tse phahameng li hloka meaho ea ho hokahanya e tsitsitseng ho fihla ka har'a li-nanometer tse mashome ho feta libaka tsa boholo ba mithara - ho ke ke ha khoneha ntle le tšebelisano-'moho ea mocheso le mechini ea Si-SiC. Sefofaneng sa lifofane, libenche tsa optical tsa satellite tse entsoeng ka litšupiso tsa ceramic li netefatsa botsitso ba ho potoloha ho sa tsotelehe potoloho e feteletseng ea mocheso. Esita le masimong a hlahang joalo ka ho lemoha maqhubu a khoheli kapa nts'etsopele ea oache ea athomo, moo botsitso ba boemo ba picometer bo leng bohlokoa, lisebelisoa tsa ceramic le Si-SiC metrology li fetoha tsa bohlokoa haholo.

Ha e le hantle, disebediswa tsena di boetse di sebetsana le botsitso le ditjeo tsohle tsa beng. Le hoja matsete a pele ho parallelepipe e nang le silicon-carbide e nepahetseng haholo a ka feta a lekanang le granite, bophelo ba yona ba tshebeletso bo ka ba bolelele ka makgetlo a 5-10 dibakeng tse sebediswang haholo. Ha e hloke oli, e hanela di-solvent tsohle tse tlwaelehileng le di-plasma, mme ha e hloke ho lekanngwa botjha ka lebaka la ho monngwa ha mongobo—ho fapana le tshepe e entsweng kapa esita le di-granite tse ding. Bakeng sa batsamaisi ba boleng ba sebetsang tlasa AS9100, ISO 13485, kapa maemo a SEMI, botshepehi bona bo fetolela ka ho toba ho fokotseng nako ya ho se sebetse, diphetho tse fokolang tsa tlhahlobo, le boitshepo bo boholo ba bareki.

Ho feta moo, botle le bokhabane ba tshebetso ba disebediswa tsena ha di a lokela ho hlokomolohuwa. Sekwere se bentšitsweng sa Si-SiC se benya ka kganya ya tshepe empa boima ba sona bo ka tlase ho ba tshepe. Rulara e otlolohileng ya ceramic air e ikutlwa e tiile empa e phahamisa ka bonolo—e loketse ho netefatswa ka letsoho dibakeng tse thata. Dibopeho tsena tse shebaneng le batho di bohlokwa dilaboratoring tsa lefatshe la nnete moo ergonomics le bonolo ba tshebediso di susumetsang mosebetsi wa letsatsi le letsatsi.

Kahoo, na disebediswa tsa ho lekanya tsa letsopa di hlalosa botjha ho nepahala ho hoholo haholo? Karabo e ho data—le lenaneng le ntseng le hola la baetapele ba lefatshe leo jwale ba di hlalosang e le maemo a tlwaelehileng. Ho tloha ditheong tsa naha tsa metrology tse netefatsang maemo a bolelele ba moloko o latelang ho ya ho bafepedi ba Tier 1 ba netefatsang dikarolo tsa EV drivetrain, phetoho e hlakile: ha ho se nepisisehe ho tlameha ho fokotswa, baenjiniere ba tshepa diserame tse entsweng ka boenjiniere.

Ha liindasteri li ntse li tsoela pele ka leeto la tsona le sa khaotseng la ho laola sekala sa athomo, 'nete e le' ngoe e fetoha e sa latoloeng: bokamoso ba tekanyo bo ke ke ba betloa ka lejoe kapa ba etsoa ka tšepe. E tla siloa, e siloe, 'me e bentšitsoe ka ceramic - le silicon carbide.

ZHHIMG INTELLIGENT MANUFACTURING (JINAN) GROUP CO., LTD (ZHHIMG) ke moqapi ea tsebahalang lefatšeng ka bophara oa litharollo tsa metrology tsa ceramic le silicon-carbide tse nepahetseng haholo. E ikhethile ka lisebelisoa tsa ho lekanya tsa ceramic, rulara ea ceramic air straight, le likarolo tse nang le silicon-carbide (Si-SiC) tse nang le lipeipi tse otlolohileng le tse sekoere, ZHHIMG e fana ka lintho tsa khale tse netefalitsoeng ka botlalo, tsa maemo a laboratori bakeng sa lits'ebetso tsa semiconductor, aerospace, tšireletso le lipatlisiso tsa mahlale. E tšehelitsoe ke litifikeiti tsa ISO 9001, ISO 14001, le CE, lihlahisoa tsa rona li tšeptjoa ke likhoebo tse etellang pele tsa theknoloji lefatšeng ka bophara. Hlahloba pokello ea rona ea metrology e tsoetseng pele howww.zhhimg.com.

Nako ea poso: Tshitwe-05-2025