Likarolo tsa granite ke karolo ea bohlokoa ea lisebelisoa tsa semiconductor tse sebelisoang ts'ebetsong ea tlhahiso ea li-microchip le lipotoloho tse kopantsoeng. Likarolo tsena li entsoe ka lejoe la tlhaho la maemo a holimo le entsoeng ka boqapi ho fihlela litlhoko tse ikhethileng tsa indasteri ea semiconductor. Granite ke khetho e tsebahalang bakeng sa lisebelisoa tsa tlhahiso ea semiconductor ka lebaka la matla a eona a ikhethang, ho tiea le botsitso ba mocheso. Sehloohong sena, re tla hlahloba mesebetsi ea mantlha ea likarolo tsa granite lisebelisoa tsa semiconductor.

1. Ho thothomela ha ho thothomela

E 'ngoe ea mesebetsi ea mantlha ea likarolo tsa granite lisebelisoa tsa semiconductor ke ho fana ka damping ea ho thothomela. Tlhahiso ea microchip e hloka tikoloho e hloekileng le e tsitsitseng, 'me ho thothomela ho ka baka tšilafalo le ho sitisa ts'ebetso ea tlhahiso. Likarolo tsa granite li sebelisoa libakeng tsa bohlokoa tsa lisebelisoa tsa semiconductor, joalo ka li-wafer chucks le mekhahlelo, ho monya le ho kokobetsa ho thothomela ho bakoang ke motsamao oa lisebelisoa kapa mabaka a kantle.

2. Ho Tsitsisa ha Thermal

Likarolo tsa granite li tsebahala ka botsitso ba tsona bo botle ba mocheso. Ts'ebetso ea tlhahiso ea semiconductor e hloka mocheso o phahameng, 'me lisebelisoa li tlameha ho boloka mocheso o tsitsitseng ho qoba liphoso kapa ho se sebetse hantle. Likarolo tsa granite li na le coefficient e tlase ea katoloso ea mocheso, e leng se bolelang hore ha li atolohe kapa li honyele haholo ka liphetoho tsa mocheso. Tšobotsi ena e nolofalletsa lisebelisoa ho boloka mocheso o tsitsitseng le ho fokotsa maemo a mocheso.

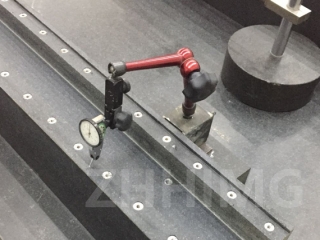

3. Botsitso ba Dimensional

Mosebetsi o mong oa bohlokoa oa likarolo tsa granite ke botsitso ba litekanyo tseo li fanang ka tsona. Ts'ebetso ea tlhahiso e hloka ho nepahala le ho nepahala, 'me lisebelisoa li tlameha ho boloka litekanyo tsa tsona tse nepahetseng nakong eohle ea ts'ebetso. Likarolo tsa granite li na le ho tiea ho hoholo le katoloso e tlase ea mocheso, ho bolelang hore ha li na monyetla o moholo oa ho fetoha ho bakoang ke liphetoho tsa mocheso kapa matla a kantle. Tšobotsi ena e netefatsa hore lisebelisoa li boloka litekanyo tsa tsona tse nepahetseng nakong ea ts'ebetso ea tlhahiso.

4. Khanyetso ea Lik'hemik'hale

Dikarolo tsa granite ha di na dikhemikhale mme di hanela dikhemikhale tse ngata tse sebediswang haholo indastering ya semiconductor. Khanyetso ya dikhemikhale e bohlokwa hobane tshebetso ya tlhahiso e kenyelletsa tshebediso ya dikhemikhale tse fapaneng tse kang di-acid, metheo le di-solvent tse ka senyang sesebediswa. Dikarolo tsa granite di ka mamella ho pepesehela dikhemikhale tsena, tsa fokotsa kotsi ya tshenyo ya sesebediswa le ho netefatsa hore tshebetso ya tlhahiso e tsamaya hantle.

5. Bohloeki

Likarolo tsa granite li bonolo ho li hloekisa le ho li hlokomela. Li na le bokaholimo bo boreleli bo etsang hore li be bonolo ho li hlakola 'me ha li na libaktheria kapa litšila tse ling, e leng se etsang hore li be ntle bakeng sa tšebeliso libakeng tse hloekileng. Bohloeki boa hlokahala ts'ebetsong ea tlhahiso ea semiconductor ho thibela tšilafalo ea li-microchip le ho netefatsa boleng bo tsitsitseng.

Qetello

Likarolo tsa granite li bapala karolo ea bohlokoa lisebelisoa tsa semiconductor 'me li kenya letsoho ho nepahaleng le ho nepahala ho hlokahalang ts'ebetsong ea tlhahiso. Likarolo tsena li fana ka ho damping ha ho thothomela, botsitso ba mocheso le boholo, ho hanyetsa lik'hemik'hale le bohloeki, tse bohlokoa bakeng sa ts'ebetso e sebetsang hantle le e sebetsang ea lisebelisoa. Ha theknoloji e ntse e tsoela pele, tlhoko ea lisebelisoa tsa semiconductor tsa boleng bo holimo e tla tsoela pele ho eketseha, 'me likarolo tsa granite li tla lula e le karolo ea bohlokoa ea lisebelisoa tsena.

Nako ea poso: Mmesa-08-2024