Granite ke lejoe la tlhaho le nang le botsitso bo babatsehang, katoloso e tlase ea mocheso, le ho tiea ho hoholo, e leng se etsang hore e be khetho ea ho khetha likopo tse ngata tsa indasteri, ho kenyelletsa le lihlahisoa tsa laser processing.Ka tlhokahalo e ntseng e hola ea mechini le lisebelisoa tsa indasteri tse nepahetseng haholo, granite e fetohile sesebelisoa se tsebahalang bakeng sa ho aha metheo ea mochini ka ho nepahala le botsitso bo eketsehileng, tse bohlokoa bakeng sa lihlahisoa tsa laser.Mona ke tse ling tsa libaka tsa ts'ebeliso ea motheo oa granite bakeng sa lihlahisoa tse sebetsanang le laser:

1. Laser Cutting Machines

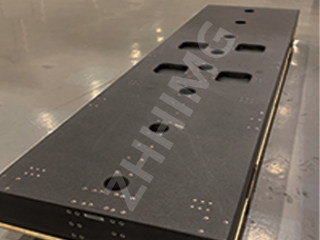

Ho nepahala ha mechini ea ho itšeha ka laser ho bohlokoa indastering ea tlhahiso.Granite ke sesebelisoa se phethahetseng bakeng sa mechini ena hobane e fana ka botsitso bo botle ba mocheso, e leng se nolofalletsang mechini ho hlahisa likhahla tse boreleli le tse nepahetseng.Coefficient ea eona e tlase ea katoloso ea mocheso e netefatsa hore setsi sa mochini ha se hole kapa ha se hokahane le mocheso nakong ea ho itšeha ka laser, ho netefatsa boleng bo tsitsitseng ba ho seha thepa e fapaneng.

2. Mechini ea ho Feta Laser

Mechini e betlang ka laser e sebelisoa ho etsa meralo e nepahetseng holim'a libaka tse thata, joalo ka tšepe, lehong le granite.Ho nepahala ho hlokahalang bakeng sa mechini ena ho etsa hore granite e be thepa ea motheo e phethahetseng kaha e tiisa botsitso le ho hanyetsa ho thothomela.Ho thatafala ha granite ho netefatsa hore setsi sa mochini ha se sisinyehe kapa ha se thothomele nakong ea ho betla, ho fella ka meralo e nepahetseng le e nepahetseng.

3. Mechini ea ho Tšoaea Laser

Mechini e tšoaeang ka laser e sebelisoa ho eketsa matšoao a sa feleng libakeng tse fapaneng, ho kenyeletsoa litšepe, lipolasetiki le lirafshoa.Granite ke thepa e ratoang bakeng sa mochini oa mochini kaha e fana ka thepa e ntle ea ho futhumatsa, e fokotsang litlamorao tsa ho thothomela mochining nakong ea ts'ebeliso.Ho tsitsa ha granite ho tiisa ho sisinyeha ho fokolang nakong ea ho tšoaea, ho fella ka matšoao a nepahetseng le a nepahetseng.

4. Laser Welding Machines

Mechini ea welding ea laser e sebelisoa ho kopanya lisebelisoa tse fapaneng, ho kenyeletsoa litšepe, lipolasetiki le lirafshoa.Ho nepahala ho hlokahalang bakeng sa mechini ena ho etsa hore granite e be motheo o loketseng.Katoloso ea eona e tlase ea mocheso le ho tiea ho hoholo ho netefatsa botsitso le motsamao o fokolang nakong ea ts'ebetso ea welding, ho netefatsa ho nepahala le ho nepahala ha weld.

5. Mechini ea ho Cheka Laser

Mechini ea ho cheka ka laser e sebelisoa ho etsa masoba a nepahetseng ka mefuta e fapaneng ea thepa, ho kenyeletsoa litšepe le lirafshoa.Ho nepahala ho hlokehang bakeng sa mechini ena ho etsa hore granite e be thepa ea motheo e phethahetseng, e fanang ka botsitso ba maemo a holimo le coefficient e tlase ea katoloso ea mocheso.Sena se tiisa ho cheka ho nepahetseng ka ho sotha ho fokolang kapa ho senya thepa.

Qetellong, setsi sa granite ke lisebelisoa tse ntle haholo bakeng sa ho aha metheo ea mochini bakeng sa lihlahisoa tse sebetsanang le laser ka lebaka la botsitso ba eona bo phahameng, ho tiea, le coefficient e tlase ea katoloso ea mocheso.Ho nepahala ho eketsehileng le ho nepahala ha mechini ena ho bohlokoa bakeng sa lits'ebetso tsa tlhahiso ea indasteri, ho etsa hore granite e be thepa e phethahetseng bakeng sa mechini ena.Ka lebaka leo, motheo oa granite o tla tsoela pele ho ba khetho e tsebahalang bakeng sa lihlahisoa tsa laser ho liindasteri tse fapaneng.

Nako ea poso: Nov-10-2023